|

|

|

Home > Products > SINTERED NDFEB MAGNET |

|

|

| |

View the big picture |

| > |

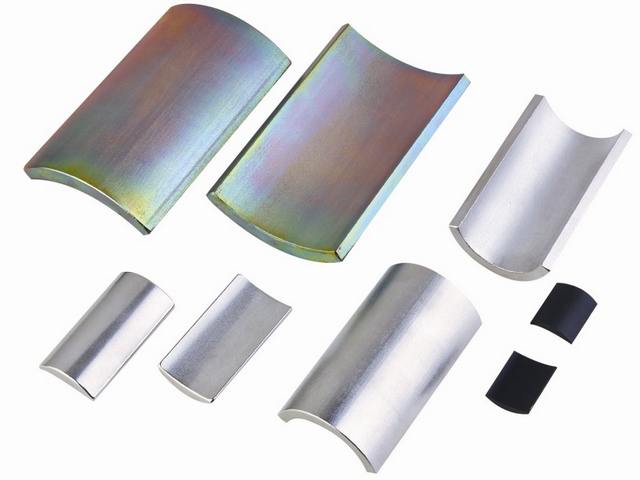

Product Name:SINTERED NDFEB MAGNET |

|

| > |

Product Id:CYC1202011 |

|

| > |

Product Category: NdFeB Magnet |

|

| > |

Product Description: |

|

|

|

Sintered NdFeB Segment Magnet

Product Description:

Producing this type of magnet with patent high temperature of M, H, SH, UH, EH series. Auto parts, especially in the motors. |

|

| |

|

Production Chart for NdFeB magnet

| PRODUCTION CHART FOR NDFEB MAGNET |

|

|

| 牌号 |

剩磁 |

矫顽力 |

内禀矫顽力 |

最大磁能积 |

温度 |

| Material |

Remanence Br |

Coercivity Hcb |

Intrinsic Coercivity Hcj |

Max.Energy Product |

Max.Working Temp. |

| Code |

| TYPE |

MT |

(KGs) |

kA/m |

(KOe) |

KA/m |

(KOe) |

KJ/m3 |

(MGOe) |

°C(L/D=0.7) |

| N30 |

1090-1140 |

10.9-11.4 |

≥796 |

≥10 |

≥955 |

≥12 |

223-263 |

28-31 |

80 |

| N33 |

1140-1170 |

11.4-11.7 |

≥836 |

≥10.5 |

≥955 |

≥12 |

247-287 |

31-33 |

80 |

| N35 |

1170-1220 |

11.7-12.2 |

≥868 |

≥10.9 |

≥955 |

≥12.0 |

263-287 |

33-36 |

80 |

| N38 |

1220-1260 |

12.2-12.6 |

≥899 |

≥11.3 |

≥955 |

≥12.0 |

287-310 |

36-39 |

80 |

| N40 |

1260-1390 |

12.6-12.9 |

≥923 |

≥11.6 |

≥955 |

≥12.0 |

302-326 |

38-41 |

80 |

| N42 |

1390-1330 |

12.9-13.3 |

≥923 |

≥11.6 |

≥955 |

≥12.0 |

318-342 |

40-43 |

80 |

| N45 |

1330-1380 |

13.3-13.8 |

≥876 |

≥11.0 |

≥955 |

≥12.0 |

342-366 |

43-46 |

80 |

| N48 |

1380-1420 |

13.8-14.2 |

≥876 |

≥11.0 |

≥955 |

≥12.0 |

366-390 |

46-49 |

80 |

| N50 |

1390-1460 |

13.9-14.6 |

≥836 |

≥10.5 |

≥875 |

≥11.0 |

374-406 |

47-51 |

80 |

| N52 |

1420-1470 |

14.2-14.7 |

≥836 |

≥10.5 |

≥875 |

≥11.0 |

390-422 |

49-53 |

80 |

| N33M |

1140-1170 |

11.4-11.7 |

≥835 |

≥10.5 |

≥1114 |

≥14.0 |

247-271 |

31-34 |

100 |

| N35M |

1170-1220 |

11.7-12.2 |

≥868 |

≥10.9 |

≥1114 |

≥14.0 |

263-287 |

33-36 |

100 |

| N38M |

1220-1260 |

12.2-12.6 |

≥899 |

≥11.3 |

≥1114 |

≥14.0 |

263-287 |

33-36 |

100 |

| N40M |

1260-1290 |

12.6-12.9 |

≥923 |

≥11.6 |

≥1114 |

≥14.0 |

302-326 |

38-41 |

100 |

| N42M |

1290-1330 |

12.9-13.3 |

≥955 |

≥12.0 |

≥1114 |

≥14.0 |

318-342 |

40-43 |

100 |

| N45M |

1330-1380 |

13.3-13.8 |

≥955 |

≥12.5 |

≥1114 |

≥14.0 |

342-366 |

43-46 |

100 |

| N48M |

1370-1430 |

13.7-14.3 |

≥955 |

≥12.5 |

≥1114 |

≥14.0 |

358-398 |

45-50 |

100 |

| N50M |

1390-1460 |

13.9-14.6 |

≥955 |

≥12.5 |

≥1035 |

≥13.0 |

374-414 |

47-52 |

100 |

| N33H |

1140-1170 |

11.4-11.7 |

≥835 |

≥10.5 |

≥1353 |

≥17.0 |

247-271 |

31.34 |

120 |

| N35H |

1170-1220 |

11.7-12.2 |

≥868 |

≥10.9 |

≥1353 |

≥17.0 |

263-287 |

33-36 |

120 |

| N38H |

1220-1260 |

12.2-12.6 |

≥899 |

≥11.3 |

≥1353 |

≥17.0 |

287-310 |

36-39 |

120 |

| N40H |

1260-1290 |

12.6-12.9 |

≥923 |

≥11.6 |

≥1353 |

≥17.0 |

302-326 |

38-41 |

120 |

| N42H |

1290-1330 |

12.9-13.3 |

≥955 |

≥12.0 |

≥1353 |

≥17.0 |

318-342 |

40-43 |

120 |

| N44H |

1330-1370 |

13.3-13.7 |

≥955 |

≥12.5 |

≥1353 |

≥17.0 |

334-358 |

42-45 |

120 |

| N46H |

1340-1400 |

13.4-14.0 |

≥955 |

≥12.5 |

≥1273 |

≥16.0 |

334-382 |

43-48 |

120 |

| N48H |

1360-1420 |

13.6-14.2 |

≥955 |

≥12.5 |

≥1273 |

≥16.0 |

358-398 |

45-50 |

120 |

| N50H |

1390-1460 |

13.9-14.6 |

≥955 |

≥12.5 |

≥1273 |

≥16.0 |

374-406 |

47-51 |

120 |

| N30SH |

1080-1140 |

10.8-11.4 |

≥812 |

≥10.2 |

≥1592 |

≥20.0 |

223-247 |

28-31 |

150 |

| N33SH |

1140-1170 |

11.4-11.7 |

≥835 |

≥10.5 |

≥1592 |

≥20.0 |

247-271 |

31-34 |

150 |

| N35SH |

1170-1220 |

11.7-12.2 |

≥868 |

≥10.9 |

≥1592 |

≥20.0 |

263-287 |

33-36 |

150 |

| N38SH |

1220-1260 |

12.2-12.6 |

≥899 |

≥11.3 |

≥1592 |

≥20.0 |

287-310 |

36-39 |

150 |

| N40SH |

1260-1290 |

12.6-12.9 |

≥923 |

≥11.6 |

≥1592 |

≥20.0 |

302-326 |

38-41 |

150 |

| N42SH |

1290-1320 |

12.9-13.2 |

≥955 |

≥12.0 |

≥1592 |

≥20.0 |

318-342 |

40-43 |

150 |

| N45SH |

1320-1380 |

13.2-13.8 |

≥987 |

≥12.4 |

≥1512 |

≥19 |

334-374 |

42-47 |

150 |

| N30UH |

1080-1140 |

10.8-11.4 |

≥812 |

≥10.2 |

≥1989 |

≥25.0 |

223-247 |

28-31 |

180 |

| N33UH |

1140-1170 |

11.4-11.7 |

≥835 |

≥10.5 |

≥1989 |

≥25.0 |

247-271 |

31-34 |

180 |

| N35UH |

1170-1220 |

11.7-12.2 |

≥868 |

≥10.9 |

≥1989 |

≥25.0 |

263-287 |

33-36 |

180 |

| N38UH |

1220-1260 |

12.2-12.6 |

≥899 |

≥11.3 |

≥1989 |

≥25.0 |

287-310 |

36-39 |

180 |

| N40UH |

1260-1320 |

12.6-13.2 |

≥955 |

≥12.0 |

≥1990 |

≥25 |

302-334 |

38-42 |

180 |

| N28EH |

1040-1080 |

10.4-10.8 |

≥780 |

≥9.8 |

≥2387 |

≥30.0 |

207-231 |

26-29 |

200 |

| N30EH |

1080-1140 |

10.8-11.4 |

≥812 |

≥10.2 |

≥2387<, /, TD ,>

| ≥30.0 |

223-247 |

28-31 |

200 |

| N33EH |

1140-1170 |

11.4-11.7 |

≥835 |

≥10.5 |

≥2387 |

≥30.0 |

247-271 |

31-34 |

200 |

| N35EH |

1170-1230 |

11.7-12.3 |

≥883 |

≥11.1 |

≥2388 |

≥30.0 |

263-295 |

33-37 |

200 |

| N38EH |

1220-1280 |

12.2-12.8 |

≥923 |

≥11.6 |

≥2388 |

≥30.0 |

287-318 |

36-40 |

200 |

| N28AH |

1050-1230 |

10.5-11.3 |

≥780 |

≥10.3 |

≥2786 |

≥35.0 |

207-247 |

26-31 |

220 |

| N30AH |

1090-1170 |

10.9-11.5 |

≥820 |

≥10.3 |

≥2786 |

≥35.0 |

223-263 |

28-33 |

220 |

| N33AH |

1130-1160 |

11.3-11.6 |

≥820 |

≥10.3 |

≥2786 |

≥35.0 |

247-271 |

31-34 |

220 | |

|

| |

| 【 Print this page 】【 Back 】 |

| |

|

|